Ultimate Source for Advanced Car Instrument Cluster Repair Service Methods

In the world of modern-day automobile upkeep, the details of instrument cluster repair service stand as an essential element of making certain the optimum performance of a lorry. By checking out the tools required, common troubles came across, and step-by-step repair work methodologies, one can furnish themselves with the knowledge required to browse the elaborate world of automobile tool collection repair with confidence and accuracy.

Value of Advanced Instrument Cluster Repair Service

Comprehending the importance of innovative tool cluster repair work is important for maintaining the functionality and precision of modern-day lorry systems. The instrument collection acts as the hub of information for chauffeurs, displaying crucial information such as rate, gas degrees, engine temperature level, and warning indications. With the advancement of innovation, tool collections have actually developed to include complex digital elements and digital screens, making repair services a lot more complex and specialized.

Appropriate fixing and maintenance of the instrument cluster are important for making certain the security and performance of the automobile. Issues with the tool collection can cause incorrect readings, malfunctions in important systems, and safety threats when driving. Advanced tool cluster repair service methods entail detecting electronic faults, rectifying sensors, and reprogramming software to bring back optimal performance.

Tools and Devices Required

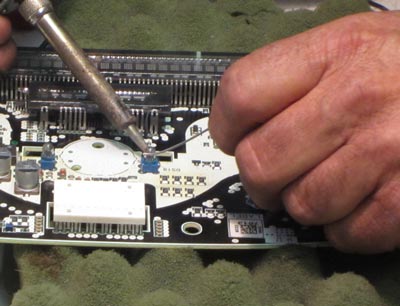

To successfully deal with the elaborate repair demands of modern car tool collections, a specialized collection of devices and equipment is crucial. Several of the secret tools required for advanced vehicle tool collection fixing consist of accuracy screwdrivers, trim elimination devices, soldering devices, digital multimeters, and analysis scanners. Accuracy screwdrivers are essential for disassembling the cluster without causing damage. Cut removal tools help in securely spying off panels and bezels. Soldering tools is required for repairing busted links or changing components. Digital multimeters are used to determine voltage, continuity, and resistance throughout analysis procedures. Diagnostic scanners are important for determining and troubleshooting digital concerns within the instrument cluster. Furthermore, having a good high quality welding torch, desoldering pump, and solder wire is necessary for performing intricate soldering work. Correct illumination, a magnifying glass, and a tidy office are also crucial for making certain precision and precision during repairs. By having actually these specialized devices and tools on hand, professionals can properly identify and solve complex problems in vehicle tool collections.

Usual Issues and Solutions

Several usual issues regularly come across in automobile instrument clusters can be effectively dealt with with targeted services. One common issue is damaged evaluates, which might result from a malfunctioning stepper motor. To address this, changing the stepper electric motor can restore exact scale analyses. One more usual concern is dim or flickering lights on the instrument collection (tahoe instrument cluster repair). This can frequently be associated to a damaged bulb or poor connections. By replacing the bulb or making certain safe and secure connections, the lights problem can be easily remedied. Furthermore, a malfunctioning odometer or display screen is a frequent problem. This could be as a result of a defective display device that requires to be replaced to restore correct capability. Finally, intermittent power or complete failure of the tool collection may come from a blown fuse or circuitry concern. Monitoring and replacing the fuse, as well as evaluating the circuitry for any kind of damages, can aid solve these power-related troubles effectively. By recognizing these typical problems and using the proper remedies, auto tool cluster functionality can be brought back effectively.

Step-by-Step Repair Work Overview

A methodical technique to repairing and detecting vehicle tool cluster problems is necessary for accomplishing exact and efficient results. To start the fixing process, the initial action is to very carefully examine the tool collection for any kind of noticeable damages such as burnt-out bulbs, fractured displays, or loose connections.

Tips for Precautionary Upkeep

After carrying out a thorough diagnostic check and finishing needed repair services on the car tool collection, applying regular preventative maintenance procedures is critical to make sure long-term performance and optimal efficiency of the lorry's important determines and indicators. To start, it is necessary to regularly examine the tool collection for any indicators of wear, such as fading screens or malfunctioning lights.

Moreover, updating the software application of the instrument cluster when needed can ensure compatibility with any brand-new functions or systems in the vehicle. It is also suggested to comply with the producer's recommended maintenance routine and guidelines for the instrument cluster to preserve its long life. By integrating these preventative upkeep pointers right into your routine lorry treatment, you can aid extend the lifespan and reliability of your automobile tool collection.

Final Thought

In conclusion, advanced car instrument collection repair work methods are crucial for maintaining the functionality of modern-day vehicles. By making use of the correct tools and equipment, resolving typical issues, and complying with a step-by-step repair work guide, specialists can effectively repair and diagnose tool collection problems. Executing preventative maintenance strategies can help lengthen the life-span of the tool cluster and protect against future concerns from occurring.

By exploring the devices required, common issues ran into, and step-by-step fixing methodologies, one can equip themselves with the understanding required to navigate the complex world of automobile tool collection repair service with self-confidence and accuracy.

A systematic approach to detecting and fixing car instrument collection issues is necessary for attaining reliable and browse around these guys exact outcomes. By following this detailed overview diligently, automobile service technicians can successfully fix and identify tool collection issues with precision and confidence.

In verdict, innovative auto instrument collection repair work techniques are crucial for maintaining the functionality of modern vehicles. By using the correct tools and tools, resolving common issues, and following a detailed repair service overview, technicians can effectively take care of and detect tool collection troubles.